Cleaning and batching PIGs

Due to the ubiquity of pipeline systems used for the safe transport of various liquids and gases over long distances, there was also a need to maintain these pipelines in working order for decades.

The primary task is to clean the internal cavity from various deposits that make it difficult to pump liquid or gas. Also, pipelines are cleaned of scale, rust and debris, which for various reasons got into it or remained after construction.

Regular cleaning of pipelines is economically justified, as it can significantly reduce the cost of pumping the product. For cleaning, a variety of in-line pigs and pistons are used, which are passed through the pipeline along with a stream of liquid or gas. The cleaning elements of the pigs (polyurethane discs, cuffs, brushes, magnets, etc.) remove deposits from the pipeline walls and take them into the receiving chamber.

The design of the cleaning pigs should ensure their safe (without stopping and jamming) passage along the entire length of the pipeline from the launch chamber to the receiving chamber. Since each pipeline has its own design features and construction defects, various cleaning pigs and pistons are used.

The specialists of APRODIT LLC conditionally divide all designs of pigs into two series based on their ability to pass various bore and obstacles in the pipeline without getting stuck or damaged:

- USO series (universal cleaning pig) - pigs pass taper up to 85% of D ext and 90 degree bends with a bend radius R = 1.5D.

- SKT series (pipe pig-gauge) - pigs pass narrowings up to 70% (in some designs up to 60% -65%) from D ext and 90 degree bends with a bend radius R = 1.5D.

SKT series pigs have a small diameter body and are equipped with elastic cleaning and sealing elements (discs, cuffs), which allow to ensure high permeability of the pipeline bore. This slightly reduces the cleaning ability of the pigs and may require several pig passes to achieve the required cleaning quality.

Since USO series pigs do not require the passage of significant restrictions, they have a larger body diameter and are equipped with more rigid cleaning elements, allowing for better cleaning of the pipeline in one pass.

Specialists of enterprises operating pipelines have different preferences and formulate requirements for an optimal pig (piston) in different ways for a specific pipeline and the specific task that this pig has to perform. The designers of APRODIT s.r.o. have put a lot of effort into offering pig designs, which can be adapted and customized to any customer requirements while maintaining the simplicity of the device, reliability and high maintainability at low cost and short production times.

We came to the conclusion that pigs with different body designs are optimal for different diameters in terms of price and technical characteristics.

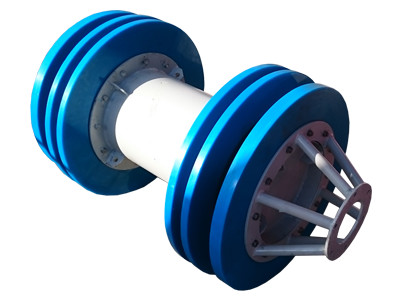

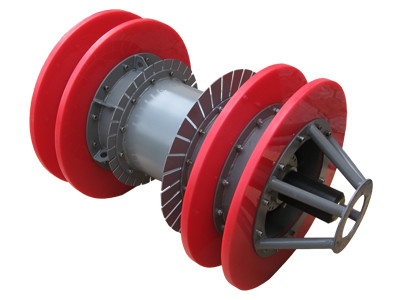

For main oil and gas pipelines with a nominal diameter of 700 mm and more, we offer in-line pigs with a welded metal body (PIG with flanges). Cleaning discs and backing discs or polyurethane collars are bolted between the pig's metal flanges.

For medium pipelines (DN 200..500 mm), the design is optimal when the pig body is made up of polyurethane bushings tightened with metal pins. Body bushings are made of solid polyurethane with a hardness of 95 Shore and more. Replaceable pig discs or wipers are clamped between the body bushings in the same way as on pigs with a metal body. This makes the body made of polyurethane bushings lighter and eliminates the risk of damaging the shut-off valves.

For infield, small pipelines, solid polyurethane pistons are optimal. When the cleaning elements wear out, these pigs are simply replaced with new ones, since replacing individual polyurethane discs or collars for small pigs is usually not cost-effective.

When analyzing the advantages and disadvantages of various designs of pigs, it should be remembered that the ability of a pig to clean the internal cavity of a pipeline is determined by the quality of polyurethane, from which the cleaning elements (discs and cuffs) are made, as well as the force with which the cleaning edge is pressed against the inner surface of the pipeline. The body of the pig serves only to fix the cleaning elements and has little effect on the cleaning ability of the pig.

When designing pig designs, APRODIT Ltd. specialists proceed from the assumption that the costs of the organization operating the pipeline are to search for and retrieve a pig without a low-frequency transmitter stuck in the pipeline is many times higher than the cost of the transmitter itself. That is why all our pigs are designed with a low frequency transmitter. Its installation in the pig is simplified as much as possible and is possible by the forces of the operating organization.

A wide range of overall dimensions of certified PNT series transmitters makes it possible to install them on in-line pistons, pigs and inspection pigs of any diameter. In addition to pigs and transmitters, we also offer a wide range of other devices, used during in-line inspections and pipeline cleaning, such as:

- NPR series low frequency receivers ,

- acoustic locators of the LKA series ,

- RTD temperature and pressure recorders ,

- PVM Inline Multichannel Profilers .

We already have ready-made solutions for many tasks related to pipeline cleaning or inspections. Even if you did not find on our website a description of the equipment that your organization needs to solve a specific problem, You can consult APRODIT LLC by email sales@pigging.tools . Our experts will definitely answer and try to find a solution.