Low-frequency transmitters PNT

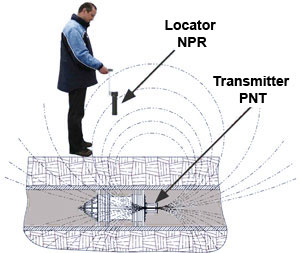

The transmitter is a generator of low-frequency (22 Hz) electromagnetic signals, which pass through metal and reinforced concrete walls, as well as through a layer of soil or water. The transmitters are usually installed on inline PIGs used for pipeline cleaning or inspections.

In-line PIGs move inside the pipeline with the flow of the transported medium (gas, oil, water, etc.). The position of the pig, equipped with a transmitter, is determined (bearing) using a low frequency locator .

Thanks to internal power supply (regular alkaline batteries) the low-frequency transmitter emits a signal for a long time - from six days to two months, depending on transmitter model and radiation mode.

This allows you to detect a stopped inline tool and track its movement along the pipeline route.

Standard modifications of PNT transmitters

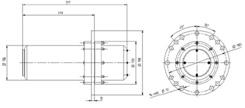

PNT transmitters are designed for installation on in-line inspection tools, cleaning pistons and pigs for pipelines with a diameter of 75 mm to 1600 mm.

Instead of the PNT-00 transmitter on the in-line cleaning or inspection pig, it is possible to install the PNT-00 transceiver , whose work can be controlled through closed metal or reinforced concrete walls.

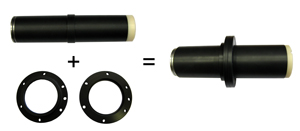

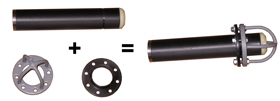

At the request of the customer, PNT transmitters can be completed with mounting flanges or other devices for reliable fastening on in-line PIGs of any design, as well as in solid polyurethane pistons .

PNT transmitters can also be installed on one-piece pistons and demountable pigs, which are launched into the pipeline through three-way ball valves.

A wide selection of standard models of PNT transmitters for various inline tools allows providing the following parameters of passability of restrictions and turns in pipelines with a diameter of 75 to 1600 mm (3 to 60 inches):

- narrowing - up to 65% D

- minimum turning radius - from R = 1.0xD

Here D is the nominal (outer) diameter of the pipeline.

At the same time, for any in-line tool with a PNT transmitter, one of the best parameters will be provided both in terms of detection range and autonomous operation time.

You can read about the correct installation of transmitters inside in-line pigs here.

Certificates, warranty and factory tests

PNT transmitters are certified in certification center TechnoProgress for work in hazardous areas according to:

- IEC 60079-1: 1998 Explosion protection "Flameproof enclosure"

- GOST 22782.3-77 Explosion-proof electrical equipment with a special type of explosion protection

- IEC 60079-10: 1995 Classification of hazardous areas

- IEC 60079-14-98 Electrical installations in hazardous areas (except for underground workings)

- GOST 12.2.007.0-75 Electrical products. General safety requirements

- IEC 529-89 Degrees of protection provided by enclosures (IP Code)

- other regulations governing the use of electrical equipment in hazardous areas

PNT transmitters are marked with explosion protection 0ExdsIIBT5.

The degree of protection of the transmitter housing corresponds to IP68 in accordance with IEC 529-89 at a pressure of 120 atm.

Certificate of Conformity GOST R low-frequency transmitters of PNT series were received in 2007.

In 2012, PNT series transmitters were included in Register technical devices recommended for use at enterprises of the fuel and energy complex of the Russian Federation.

Certificate of Conformity ТР ТС 012/2011 "On safety of equipment for work in explosive atmospheres" for PNT transmitters was received in 2013. This certificate of conformity to the technical requirements of the Customs Union certifies the compliance of the transmitters with the requirements of technical regulations and ensures the circulation of certified products on the territory of Russia, Belarus and Kazakhstan without additional requirements and without additional assessment procedures.

During factory acceptance and before shipment to the Customer, the finished PNT transmitters are tested in a hydraulic test bench (pressurized). PNT-08 and PNT-06 transmitters are pressurized with a pressure of 120 atm. PNT-04 transmitters are pressurized with a pressure of 150 atm. And PNT-00 transmitters are pressurized with a pressure of 200 or 300 atm. The pressure depends on the pipeline in which the particular transmitter will be used. It is usually chosen at least 30% higher than the design maximum pressure in the pipeline.

During these factory tests, the switched on PNT transmitter is placed in a hydraulic stand, which is filled with water. After that, the pressure in the hydrostand rises to the set value, which is monitored using a pressure gauge. The transmitter is held at a given pressure for 3 minutes. Then the pressure drops to zero as quickly as possible (no more than 1 second). This simulates the rapid release of pressure in the receiving chamber. The cycle is repeated 3 times. After that, the transmitter is kept at a given pressure for 2 hours.

The performance of the transmitters during the tests is monitored using a low-frequency NPR-00 receiver , which is located at a distance of 2.5 m from the hydrostand and registers the presence of a signal at a frequency of 22 Hz from the tested PNT transmitter and its strength. Light and sound indication of the received signal is analyzed. Only transmitters that have passed the tests without comments are sent to the Customer. Any PNT transmitter whose signal disappears or weakens during at least one of the tests is rejected and sent to the bulkhead to find out the reasons.

PNT transmitters are produced serially according to TU 4276-001-96335610-2007.

The manufacturer provides a 12-month warranty for all PNT transmitters.

Convenience and ease of use

Transmitters are equipped with LED light indication, with the help of which the operator receives visual feedback on the mode in which the transmitter emits and what is the remaining battery life for operation in this mode.

PNT transmitters can be switched on and off remotely without removing from the inline tool. If the operator needs the maximum detection range for a specific job, Then you can use the remote control to switch the radiation mode to continuous with double power (see mode # 4 below).

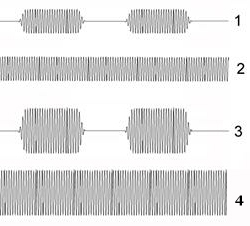

You can also remotely assign one of four modes of radiation:

- in bundles

- continuous

- double power packs

- double power continuously

By default (after replacing the batteries), the transmitter starts emitting in burst mode (1). In this mode, the battery life of the transmitter is maximum.

Remote switching the transmitter on and off, switching radiation modes, dependence of the operating time and detection range on the selected mode and other important information are described in detail in the operating manual.

A short video instruction on working with PNT transmitters and NPD locators is posted on the website YouTube. At the request of the Customer, a DVD with this video instruction is delivered with each batch of devices.

Video instruction on working with PNT transmitters and NPR locators

Immediately after installing the batteries, the PNT transmitter starts operating in the "pack" radiation mode. For greater convenience and use of all the capabilities of PNT transmitters, a compact remote control is included in the delivery set.

The remote control allows you to turn on, turn off and switch the transmitter modes without opening the case. In this case, the transmitter can remain installed on the pig.

The video tutorial uses an infrared transmitter built into the NPD locator for this purpose.

Operating time and batteries

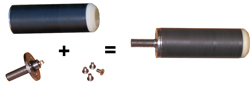

Conventional 1.5V alkaline or lithium batteries are the source of energy for PNT transmitters. The batteries are easy to replace.

Nickel-cadmium (NiCd) and nickel-metal hydride (NiMH) transmitters can also be used in APRODIT transmitters batteries of the appropriate standard size with a voltage of 1.2V, as well as lithium batteries (for example Energizer Ultimate Lithium , AA and AAA) with a voltage of 1.5V. Thus, reliable operation of PNT transmitters is guaranteed even at extremely low temperatures up to minus 40C.

The transmitters are based on verified circuitry solutions, an extended supply voltage range and materials that are unique in their properties are used. Also, original layout solutions were applied. As a result, PNT transmitters have a long battery life and a good detection range by a locator.

With careful attitude, PNT transmitters operate reliably for many years, requiring only periodic replacement of batteries.