Utility PIGs of USO series

The PIGs of USO series are designed for cleaning of pipelines from wax deposits, rust, scale, dirt and other debris. Also these PIGs can be used for displacement or removal of different petroleum products, multi-phases liquids or gases. Cleaning is carried out by elastic polyurethane discs (or cuffs).

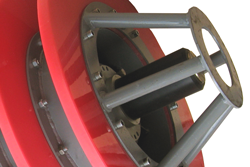

The body of USO PIGs for 20'' pipelines (and smaller) is made of hard polyurethane bushes tightened inside by curved steel rods.

Due to low weight and large number of polyurethane discs these USO series PIGs are effectively sealed in the pipe and do not lose tightness in pipelines of considerable length.

Because metallic body is absent in USO cleaning PIGs of small and medium diameters then the signal of 22 Hz transmitter is not weakened even when the transmitter is completely inside the body of the PIG. It allows installation of a powerful transmitter without making the PIG longer. So ability to pass sharp bends and different narrowings in small diameter pipelines is preserved..

Also when USO PIGs with non-metallic body are used it excludes any damage to the pipeline valves even if they were, for some reason, not fully opened during the pipeline treatment.

In addition to Transmitters on USO one can install also Data Loggers (for registration of pressure and temperature along the pipeline), Transceivers, magnetic blocks to clean the pipeline from the cinders of electrodes, wires and other metal debris as well as metallic wire brushes to clean the walls of solid deposits including calcium scale.

Proven solutions

The PIGs of USO series have dimensions and proportions adjusted in multiple applications. The configuration of the pigs allows the passage of pipeline restrictions of up to 85% of the outer diameter (for cleaning of pipelines with contractions of up to 70% outer diameter gauging pigs of SKT series can be used).

Developed front bumper of USO PIGs makes it possible to pass equal diameter tees without bars and with lower position of the connected pipe as well as gate valves with a wide groove.

Body parts of USO PIGs for pipelines with diameters up to DN 20"" are made thick-walled from rigid polyurethane (or polyamide). Their disintegration is practically impossible.

Possibility to damage pipeline valves is completely eliminated when USO PIGs are used. Because a contact between metallic parts and the valves is not possible under any circumstances. For the same reason USO pigs can be absolutely safely used in pipelines with an internal flow coating, as well as in pipelines made of polyethylene pipes.

Polyurethane cleaning and supporting disks (or cuffs) of the PIGs are made from high wear-resistant polyurethane with hardness 75 ... 85 units on a scale Shore A.

Scrapers USO pass:

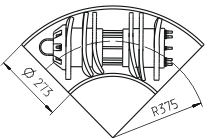

- Curved bends with a radius R = 1.5xD (possible option for R = 1.0xD)

- Equal diameter tees with the lower outlet location

- Incuts protruding inside pipeline

- Wedge and gate valves

Passage of the bend, steeply curved in accordance with GOST 17375

In-line pigs of USO series were certified in accordance with TR CU 010/2011 "On the safety of machinery and equipment".

Certificate of Conformity of the Customs Union - a document certifying the conformity of products with technical regulations and providing of certified products in Russia, Belarus and Kazakhstan without additional requirements and without additional assessment procedures.

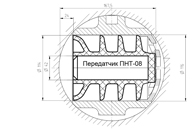

Scrapers USO can be equipped with low-frequency transmitters of PNT series.

A choice of several transmitters PNT with different sizes allows us to equip by a transmitter any USO PIG for pipeline diameters from 3" to 56".

Together with the transmitter on USO PIG one can also install Data Logger RTD-00, which allows to construct graphs of pressure and temperature distribution along the pipeline, as well as a graph of pressure drop on the PIG.

In pigs USO with metal housing (used for cleaning of pipelines with diameter 24" or more) the transmitter is located at the rear of the pig. It is protected by welded bumper (the basket). In this case the transmitter is located so that its signal is not attenuated by metallic body of the PIG.

By this link one can read an article about optimal installation of low-frequency transmitter in the utility in-line PIG with metallic body.

Benefits of USO PIGs with demountable non-metallic body

The main advantage of the PIGs with non-metallic body is a significant reduction of the risk to damage the pipeline valves.

Small diameter PIGs USO with cleaning polyurethane discs and easily disassembled non-metallic corpus also have certain advantages in the total length of a pipeline which they can clean, in comparison with solid-casted polyurethane PIGs. Indeed total length which can be cleaned by one set of USO PIG discs is larger than the length cleaned by solid casted piston. Let's consider why.

The PIGs of small diameter are usually used repeatedly (typically for cleaning infield pipelines or pipelines between offshore platforms). Before the next launch in the pipeline the PIG must be cleaned. Thus with the existing technologies the pigging imply an inspection of the PIG between two launches. So one can see and fix an uneven wear of the cleaning discs on the PIG.

With wear of one edge of the cleaning disk, one can turn the disk around and set it back to the same PIG. Thereafter the disk can effectively clean the pipeline about the same distance. During the the PIG inspection it is also possible to swap the most and the least worn disks on the PIG. Or replace individual badly damaged disk. Although these jobs require certain amount of time from the staff but they significantly improve the efficiency of polyurethane products usage.

Manufacturing of spare polyurethane discs is easier and cheaper than manufacturing of polyurethane-casted pistons. After all, the body of a PIG is almost no wear. While supplying of spare polyurethane disks can be performed by many local manufacturers based on the drawings of discs that on request of the Buyer are included in the delivery package along with USO PIGs..

Additional advantage of USO PIGs is their light weight, which is achieved by minimizing of corpus weight, while all the requirements for durability and reliability are kept. This feature gives the advantage during transportation, as well as during launch via launching chambers located on unprepared pads and sites.

Designation of USO cleaning PIGs in a request

The diameter of the leading disk is chosen equal to the inner diameter of the pipe. While ordering the PIG it is important to specify not only the external diameter of the predominant pipeline but also the pipe wall thickness in the pipeline where it is supposed to use the PIG.

Cleaning PIG USO-XXX-ZZ- [T B C], where

- XXX - external diameter of the pipeline in millimeters,

- ZZ - prevailing pipe wall thickness in millimeters,

- Specify T when USO is ordered with transmitter, B - when the PIG is ordered with metal brushes, C - if instead of supporting discs polyurethane cuffs are requested.

Example. Cleaning PIG of USO series for the pipeline which linear part is made of pipes with outer diameter 530 mm, prevailing wall thickness is 10 mm and the PIG should go with installed transmitter ought to be designated in the request as following:

Cleaning PIG USO-530-10-T

Options

Instead of low-frequency transmitter PNT in a PIG one can install a low-frequency transceiver PPNT, which has the same attachment dimensions. The main difference of the transceiver is that it can be switched to the lowest level of power consumption (sleep mode) right through the metal walls of the closed launching chamber of pipeline walls. In this case, a PIG with the transceiver can be located inside the launching chamber under pressure for several days or even weeks. Thereafter, it can be switched on to function as a conventional transmitter 22 Hz without opening the chamber.

To send a command through thick closed metal (or reinforced concrete) wall special transmitter is used, which also operates at 22 Hz. As the transmitter (remote control) a modified transmitter PNT-04 is used now. In future the function of 22 Hz remote control is planned to be added to modified LF locator NPR-00.

Thanks to the dismountable corpus from polyurethane (or polyamide) bushings, various modifications and configuration of USO pigs are possible. The modifications include changes in the number and location of polyurethane cleaning and supporting discs, installation of various additional equipment, magnets and brushes.

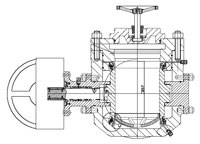

We can deliver short version of SKT PIG with the body made of rigid polyurethane bushes or all-polyurethane solid-casted PIGs for automatic launching via three-way Ball Valve.

In all these short PIGs one can insert low frequency transmitter to track and search the PIG while it is moving through a pipeline.

The illustration shows short PIG for three-way Ball Valve in the pipeline with diameter DN = 12" (300 mm) and for diameter DN=4" (100 mm).