Our products

Multichannel in-line calipers

Electronic calipers PVM with navigation modulus for geometry inspections of oil and gas pipelines.

Low-frequency transmitters

PNT transmitters (22 Hz) for installation on in-line inspection tools and cleaning pigs.

Location & tracking receivers

Receivers NPR for detection and registration of signals from low-frequency (22 Hz) transmitters.

Pipeline data loggers

Pressure and temperature recorders RDT with gyroscopes for installation to in-line pigs from 4" to 56"

Acoustic amplifiers with geophones

Locators LKA for tracking and searching of an in-line pig by sound.

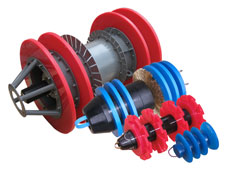

Cleaning and gauging PIGs

Utility pigs, solid casted polyurethane pigs, pigs with metal brushes.

Spare parts for in-line PIGs

Discs, cups, gauging disks, disc brushes.

OEM parts for inspection tools

Odometers and odometric systems, electronic modules for in-line tools and more.

Non-standard equipment development

Development of custom equipment.