Pipeline Data Loggers RDT

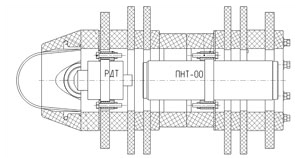

Data loggers RDT were designed for installation on in-line pigs from 4" to 56" in order to register pressure and temperature of the pumped medium, as well as for recording pressure difference propelling the pig.

On-board navigation modulus registers angular velocities and accelerations with sampling frequency up to 512 Hz. Optional pressure switch allows to extend battery life due to low-power standby mode. The software for Windows computers is supplied with the devices.

Data loggers RDT work in natural and industrial gases, oil, oil products, multiphase media (gas + liquids), water (including sea water).

At the same time, a low-frequency transmitter can also be installed inside the pig. It will allow to track the pig and search it if the pig stops in the pipeline using low-frequency receiver .

Before installation on the pig, the data logger RDT is connected via USB cable to a computer. User sets the frequency for navigation data storage during the run using computer program Service_RDT.

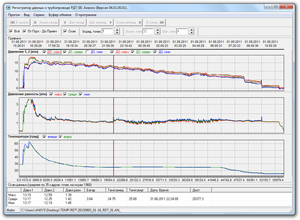

After running through a pipeline, the RTD is reconnected to the computer and the data from the internal memory of the device is copied to the computer. Specialized program Analysis_RDT is used to analyze the data.

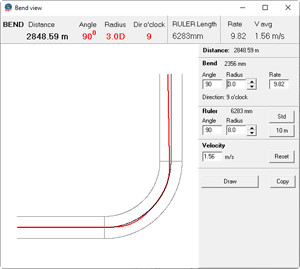

User can see the following graphs: pressure, differential pressure, temperature, accelerations, angular velocities. Also the graph of all pipeline bends and curvatures encountered by the pig with data logger is calculated and drawn by the program.

In this data processing program user can view graphs with both time and distance sweeps along horizontal axis. Under the graphs all numerical values for current cursor position on the graphs are displayed in tabular form.

Tabular data and graphs from the Analysis_RDT program are used for reports and contain initial numerical data about the pipeline.

According to the graph of pressure difference on the pig user can evaluate the magnitude and rate of deposits growth on the pipeline walls. This analysis allows to choose optimal time intervals for cleaning of the pipeline.

By selecting particular bend on the graph of bends, user can visualize this bend in a special window and automatically calculate its angle. Also in this window user can estimate the radius of the bend, if there were no significant changes in the speed of the pig motion during passage through this bend.

Design and principle of operation of RTD data loggers

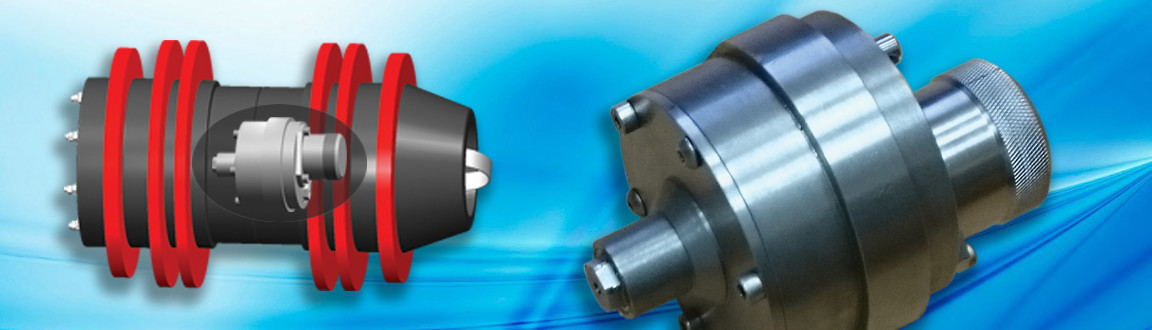

Data loggers RTD have strong sealed metallic cylindrical body made of stainless steel. In the middle of the device housing there is a flange to fix RDT inside a pig.

Data logger RDT has not only absolute pressure sensor but also high accuracy differential pressure sensor. There are battery cover and electronics cover. LED indicator in electronics cover shows to operator the mode of RDT work. An electronics modulus is made of several printed circuit boards which connected together mechanically to form a strong triangular prism located inside the housing.

To power data logger one lithium battery size D or DD with a voltage of 3.6 V is used. It provides a significant operating time of the data logger and ease of replacement. The battery life can be significantly extended due to pressure switch. The device can work in a wide temperature and pressure ranges.

There are following sensors inside data logger RTD: absolute pressure sensor (have to be in front of the pig), pressure difference sensor, device's body temperature sensor, electronics module temperature sensor, 3D accelerations sensor, 3D angular velocities sensor, amperage sensor, battery voltage sensor.

Certificates, warranty and factory tests

RDT data loggers were certified for compliance with TR CU 012/2011 in the certification center TECHNOPROGRESS for work in hazardous areas according to :

- IEC 60079-0:2011,

- IEC 60079-11:2011,

- IEC 60079-14-2013,

- IEC 60079-0: 1998,

- IEC 529-89

- and other regulatory documents regulating the use of electrical equipment in hazardous areas.

Data loggers RDT are marked with explosion protection label 0Ex ia IIB T3 Ga X

The degree of protection of the transmitter housing corresponds to IP68 in accordance with IEC 60529:2013 at a pressure 15 MPa.

Before delivery to a customer, the data loggers are pressurized and calibrated at a pressure of 180 bar (for higher pressure please request).

RDT are serially produced according to TU 4276-001-96335610-2015.

The manufacturer's warranty is 12 months. Service life not less than 5 years.